In the intricate world of manufacturing, one process stands out for its versatility and essential contribution to a myriad of industries—extrusion. But what exactly is an extrusion machine, and how does it work its magic in shaping materials into desired forms? Let's delve into the fascinating working principles behind this transformative technology, exploring its mechanisms, applications, and significance in modern production lines.

Understanding Extrusion Machines: Basic Concepts

At its core, an extrusion machine (often referred to as an extruder) is a device designed to process raw materials by pushing them through a die to create continuous profiles or shapes. These machines are instrumental across various sectors, including plastic, metal, food, and even pharmaceutical industries, where they play a vital role in mass-producing consistent, high-quality products.

The Anatomy of an Extrusion Machine

An extrusion machine typically consists of several key components: a feed system, a barrel encased with a heating system, a screw that rotates within the barrel, a die at the end of the barrel, and finally, a cooling system or take-off equipment for the newly formed material.

1. Feed System: This part ensures a steady supply of raw material pellets into the extruder's hopper, facilitating an uninterrupted production process.

2. Barrel & Screw: The barrel is heated to melt or soften the material, while the rotating screw mixes and propels it forward. The screw's design—featuring feed, compression, and metering zones—optimizes material flow and pressure buildup necessary for extrusion.

3. Die: At the heart of the process lies the die, a precision-engineered tool that imparts the desired cross-sectional shape to the molten material as it exits the barrel.

4. Cooling System: Post-extrusion, the freshly shaped material is cooled rapidly using water baths, sprays, or air coolers to solidify its form and dimensions.

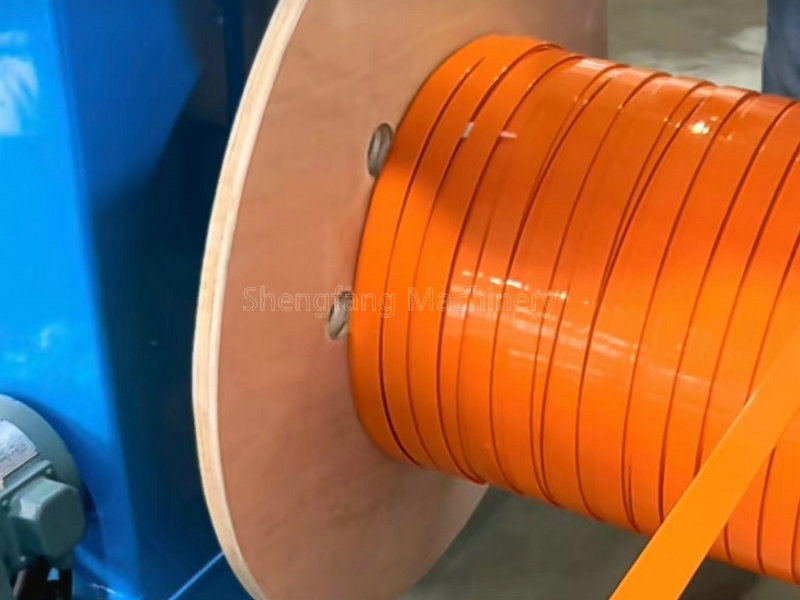

5. Take-off Equipment: Finally, cutting devices or winding systems collect and package the extruded product, preparing it for further processing or direct shipment.

The Extrusion Process: From Raw Material to Final Product

The journey of material transformation within an extrusion machine unfolds through several stages:

1. Feeding & Conveying: Raw materials enter the hopper and are conveyed into the barrel by the rotating screw.

2. Heating & Melting: As the material advances through the heated barrel, friction between the screw and barrel wall, combined with external heating elements, raises its temperature until it reaches a semi-liquid state.

3. Mixing & Homogenization: In the compression zone, the intensifying pressure from the screw flights further mixes and compresses the melt, ensuring homogeneity before it reaches the metering zone.

4. Shaping: Upon reaching the die, the uniformly melted material is forced through intricately designed passages, emerging with a predetermined shape dictated by the die's configuration.

5. Cooling & Solidification: Immediately after extrusion, cooling mechanisms engage to solidify the newly formed profile, preserving its shape and size stability.

6. Cutting & Collection: The final step involves cutting the extruded material into desired lengths or rolling it onto spools, ready for packaging or additional finishing processes.

Applications Across Industries

The versatility of extrusion machines makes them indispensable across numerous domains:

- Plastic Manufacturing: From pipes and cables to toys and medical devices, extrusion molds plastic into countless everyday items.

- Metal Industry: Aluminum and steel profiles for construction, automotive components, and even household appliances benefit from extrusion's precision.

- Food Industry: Spaghetti, crisps, and even pet foods are produced via extrusion techniques tailored to food processing needs.

- Pharmaceuticals: Tablet formulation and drug delivery systems leverage extrusion for creating precise dosage forms.

Conclusion: The Power of Extrusion Technology

The working principle of an extrusion machine encapsulates a marvel of engineering efficiency, transforming diverse raw materials into precisely shaped products that fuel innovation and production across industries. Its ability to mass-produce complex shapes with consistency and speed underscores its paramount importance in contemporary manufacturing landscapes. By understanding the mechanics of extrusion, we gain insight not only into the creation of everyday objects but also the advancements driving future technological possibilities